by Barbara Hahn

Tobacco Oscillations: Changing Size on the Spot

Cropscapes offer new perspectives on the size of tobacco cultivation units over the centuries. In other chapters we have analyzed the life-cycle flexibility of the tobacco plant—that is is a perennial grown commercially as an annual. We have also spoken of its geographical mobility. Here we focus on a single location, the Virginia-Carolina border where tobacco has been produced consistently from at least the 1600s to the 2000s. By keeping place constant we can trace oscillations in the size of the farm, or cultivation unit, that spooled out across three centuries. These size oscillations show how non-plant elements in the cropscape—legal and technological changes—interacted in the reconfiguration of both spatial size and labor organization. Changes in the size of tobacco farms in a single location demonstrate a non-linear history that moves from small to large to small to large again under different legal and technological frameworks. Recognizing the oscillatory nature of the tobacco farms demonstrates that cropscapes need not move to change, revealing and reconfiguring elements in the classic tobacco cropscape.

When the first shipment of tobacco to England brought a high price in 1617, colonial settlers “stopped bowling in the streets and planted tobacco in them.” For the next century, English colonists cultivated tobacco on both small farms and large plantations. Virginia Company policies and the House of Burgesses (the colonial legislature), however, favored planters with more resources. Stint laws that were intended to limit supplies and thereby raise prices limited the number of tobacco plants per person, while headrights granted land to those who paid the passage of bound laborers. These provisions resulted in early engrossment of the best land in the hands of planters with the money to import labor. The laws and their effects created grand plantations along the Chesapeake waterways—some of the oldest fortunes in British America. Nonetheless the crop was famous for the opportunities it provided even to smaller-scale and poorer producers, and a medley of small and large farms co-existed up to the 1720s.

At that point, with the introduction of inspection laws in the 1720s that approved for export only high-quality tobacco, and forbade sales of the plant’s second growths, economic historians identify a “steady upward drift” in the size of tobacco farms and slave labor forces. The tendency was there already: slaves already existed in the region, of course, and laws after 1660 demonstrated emerging distinctions between slaves and servants. But the changing legal landscape of the 1720s decisively favored planters who could command large numbers of workers at crucial harvest points, disadvantaging smallholders. This second phase in the oscillation of tobacco farm-size in Virginia created a cropscape of large cultivation units that employed and facilitated a patriarchal ideology characteristic of the plantation system. As production units, these plantations mirrored the manors of medieval Europe, with planters viewing the entire household as familial, organized in webs of mutual responsibility and obligation. “Thirty of my family are down with the smallpox,” a planter wrote to a merchant in the 1820s-30s, as if his slaves were his children. Thus the colonial inspection laws combined with provisions granting land to planters who had labor, and the laws governing and taxonomizing those laborers, all contributed to the changing size of the tobacco cropscape in eighteenth-century British America.

Federal law, in the form of the Emancipation Proclamation of 1863, initiated a third phase of oscillation as the size of tobacco farms shrunk after the Civil War. Though landownership mostly remained concentrated in the hands of the former slave-masters, the scale of cultivation dropped as sharecropping re-organized what had been slave labor. Not only the organization of production but the nature of cropping practices changed in consequence. Sharecropping relied on annual credit: farm families waited for harvest for their pay and owed landlords and storekeepers for rent and food and seeds and fertilizer. Each group provided credit to the others, with all bills due at the end of the year. To keep all parties afloat, harvest and curing methods emerged that allowed a new annual production cycle of several harvests. Instead of chopping down the whole plant, as had been done for centuries, a new system emerged, organized around plucking individual leaves. Harvesting individual leaves, then going through the fields again to pluck another set of leaves, meant barns could be filled for curing and then cleared out for another round. Farmers used extended-family labor systems to adopt the new techniques. “We barned Uncle Montgomery on Monday. Saturday was Uncle Dewey’s day. All of us worked together. No one would barn Wednesday or Thursday . . . because that would mean adjusting the fire on Sundays and, well, this is the South.” Thus the nuclear family on the small farm was one part of a larger web of labor arrangements and technical strategies needed to make the whole cropscape work in its new configuration.

Another new element in the post-emancipation system was chemical fertilizer. Fertilizers allowed small postbellum farmers to plant on poor, sandy soils, producing a brighter, milder tobacco. Here too the state aided the adoption of new technology, new elements of the cropscape—not through legislation but by providing chemists to test fertilizer brands and to adjudicate disputes over quality. These chemists worked at the new North Carolina Agricultural and Mechanical College, one of the land-grant colleges established after the passage of the Morrill Act in 1862, which also contributed instructions in the harvesting and curing methods that reliably made tobacco bright, yellow, and mild enough to inhale. Bright tobaccos turned tobacco manufacturing into Big Business in the last decades of the nineteenth century, as tastes shifted towards smoking. Small firms that had previously produced mostly chewing tobacco were absorbed by a large-scale consolidated producer of cigarettes, the infamous combination (some, imprecisely, call it a monopoly) known as the American Tobacco Company. Big Tobacco bought tobacco from small farmers in warehouses, with auctioneers to help farmers sell and manufacturers or middlemen buy a small pile of leaf in a basket—just a hundred pounds or so at a time.

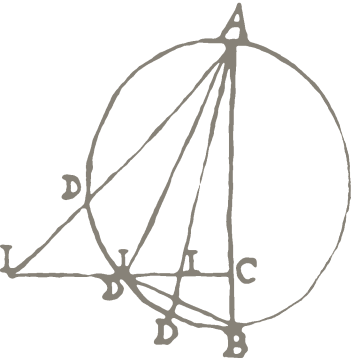

After the US Civil War, tobacco farms along the border of Virginia and North Carolina shrunk back to the small size that had disappeared with the rise of antebellum plantations. The small farms used larger labor forces to remain viable, and extended families rotated their labor across the farms of all family members for harvest and curing. Image courtesy of the North Carolina Collection, University of North Carolina at Chapel Hill.

Thus large-scale tobacco plantations from the colonial and ante-bellum periods became small farms under new post-bellum regulatory and labor systems. In the 1930s, New Deal policy locked farm size into its small space for a few decades more. Its federal support for agricultural prices limited how much each farmer could sell and therefore capped farm sizes. However, in the last three decades of the twentieth century, the size of cultivation units grew once again, this time to justify investment in new harvesting machines. The post-bellum method of harvest, the plucking of individual leaves, became embodied in a machine patented in 1971. Purchasing and using such a machine was only viable for farmers who had larger plots to work than the New Deal allotments permitted. Earlier legal changes had paved the way for mechanization: in 1961 and 1962, new laws allowed farmers to sell or lease their tobacco allotments to other farmers within their county, which allowed farms to grow large once again.

The new larger farms were the fourth phase of size oscillation in the tobacco farms of the Virginia-Carolina region. Once again this transformation was catalyzed by interlocking changes in law and technology: the softening of the limits on farm size that had emerged in the postbellum South, hardened by New Deal policies in the 1930s, and the harvesting machine that made only larger farms profitable. Other sociotechnological changes ensued from this single invention: the move to bulk curing eliminated the labor of women who had looped individual leaves onto sticks for men to hang in the curing barns. As the system shifted along with the increasing farm size, the labor arrangements of nuclear and extended families also changed, yet the mechanization of harvest and curing was sold to farmers as a return to family farming -- a way to be rid of sharecroppers and wage workers. The expertise of the USDA and the North Carolina State University contributed to the development and marketing of the machines, and the harvesting machine patent was assigned immediately to R. J. Reynolds Tobacco Company, indicating the likely support of the biggest buyer of the region’s tobacco for the mechanization of cultivation and its associated growth in farm size.

The size of tobacco cropscape changed repeatedly on the Virginia-Carolina border as a result of larger trends in U.S. history. From a crop that suited small and large farmers alike, in the eighteenth century tobacco became a plantation crop that only rewarded large-scale producers and that used slave labor. After the Civil War, emancipation of the slaves and changing credit arrangements shrank the scale of tobacco production to small sharecropping farms, and in the 1930s, the small scale of production became law as allotments limited how much each farm could sell. This scale of production expanded once again when government permitted the allotments to be sold or leased, creating consolidated farms that repaid mechanization in ways that smaller crops could not. While the location of production stayed the same, the cropscape’s inputs changed dramatically with each oscillation phase. Fertilizer helped make farms small post-bellum; in the 1970s farms grew to accommodate the harvesting machine, which required regular infusions of gasoline if it were to do its labor-saving work. Mechanizing the tobacco harvest required gasoline. This demand linked tobacco farms to new markets. It also solidified cultivators’ relationships to older ones--the corporations that bought their produce.

Tobacco’s oscillations are a simple history that unveils how many different elements play a role in size, and it complicates the perceived causative relations among them. The plant did not dictate the farm size, but the entire cropscape incorporated and caused and was caused by changing sizes. Likewise, the mosaic of production systems for coffee in Ethiopia are pure history.